Scientists develop a stretchable super-repellent material that resists water, acids, and solvents while stretching up to five times its original size without losing performance.

Scientists have developed a new elastic material that can repel almost any liquid—even aggressive acids, alkalis, and solvents—while stretching up to five times its original length without losing its protective properties.

These materials are known as super-repellent or superomniphobic materials. Unlike standard water-repellent surfaces, they resist a wide range of liquids, making them highly valuable for advanced technologies such as flexible electronics, wearable devices, and soft robotics.

According to co-author Arun Kumar Kota, associate professor of mechanical and aerospace engineering at North Carolina State University, superomniphobic materials can repel nearly any liquid, including highly corrosive chemicals. This makes them ideal for soft robots and other devices that must operate in harsh environments while bending, stretching, or changing shape.

The Problem with Traditional Super-Repellent Materials

Typically, superomniphobic materials are made by spraying a nanoparticle solution onto a surface. This creates a microscopic rough coating that prevents liquid droplets from sticking.

However, this protective layer easily peels off when stretched. Even doubling the material’s length can destroy its liquid-repellent properties.

In earlier research, Kota’s team improved durability by adding tiny surface pillars, known as microprotrusions, ranging from 10 to 100 microns in size. These structures helped reduce tension on the protective layer during stretching, allowing the material to maintain its performance to some extent.

Laser Technology and Machine Learning Improve Performance

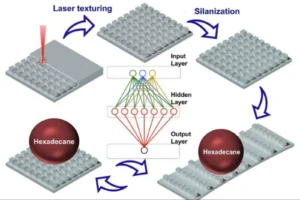

In their latest study, the researchers went further. Instead of using spray coating, they applied laser ablation—a technique that uses laser pulses to shape materials at the microscopic level.

This method allowed them to create both:

-

Microprotrusions

-

A rough surface structure responsible for liquid repellency

To find the best laser settings—such as power, speed, and pulse frequency—the team used machine learning. The system analyzed which parameters produced the ideal “grazing angle,” meaning how easily liquid droplets slide off the surface.

This approach eliminated the need for thousands of trial-and-error experiments.

Strong, Flexible, and Environmentally Friendly

The new technique was tested on a siloxane elastomer treated with fluorocarbon silane. The final material:

-

Maintained its superomniphobic properties

-

Stretched up to five times its original length

-

Withstood more than 5,000 stretching and compression cycles

Importantly, the process does not rely on harsh chemical solvents, making it more environmentally friendly and cost-effective.

Future Applications

This breakthrough opens the door to durable, flexible materials for:

-

Soft robotics

-

Wearable electronics

-

Medical skin patches

-

Protective coatings in harsh chemical environments

The new platform for producing stretchable super-repellent materials could significantly advance next-generation flexible technologies while reducing environmental impact.